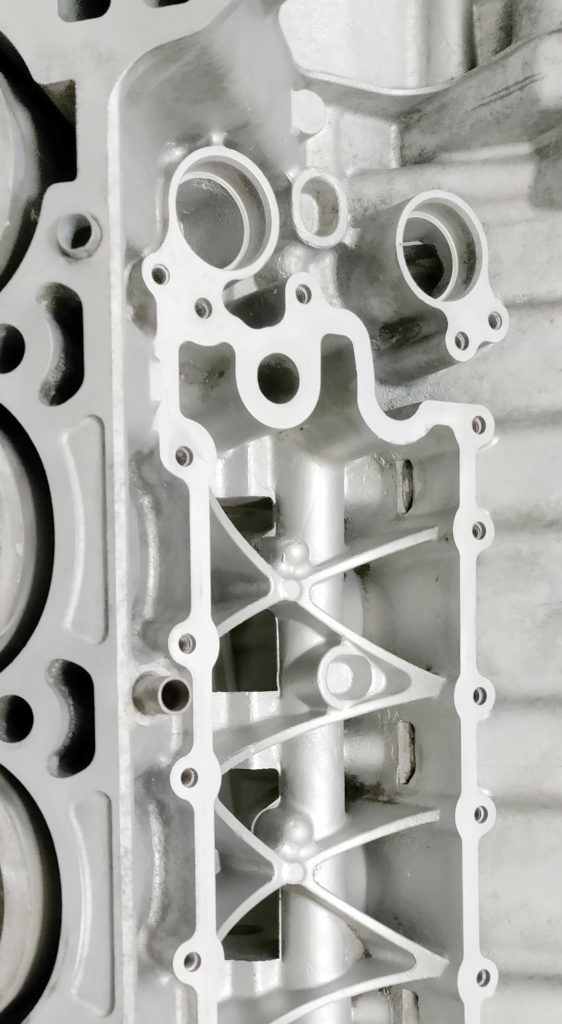

Vapour blasting (wet blasting) is a non-aggressive method of reconditioning non-ferrous metals. It eliminates the dirt, contamination and corrosion products but not the surface material so parts retain their original dimensions with a stunning finish, far superior to sandblasting.

Vapour blasting works by expelling a slurry of media which are accelerated and atomised by pressurised air and water. Abrasive particles in the slurry are prevented from being embedded in the metal by the water component. The water is also used to propel the abrasive media to the surface of the component, but at the moment of impact the water acts as a flushing agent to remove surface debris. This thin film of water reduces the degree of surface deformation allowing a delicate cleaning action.

This makes it perfect for use on almost any car parts from classic cars all the way through to more modern motors as well as motorcycles, ATV, Boat, agriculture, industrial components, and so much more.

Vapour Blasting is also commonly referred to as Hydro Blasting, Aqua Blasting, Wet Blasting and Vapor Honing.

Vapour cleaning removes:

- paint,

- grease & oil,

- corrosion and rust,

- other contaminants, chemicals and residues.

Find out more about vapour blasting

Our FAQ page will tell you everything you always wanted to know about vapour cleaning.